Ejection system upgrade

Hi, it's Jaka from the mechanicial team again.

During the bench test we managed to test the newly manufactured components of our experiment ejection system which function as an upgrade. In the integration week in Bremen it turned out that arming the ejection system is quite difficult and we had to do some updates.

The image below briefly shows how the ejection system works.

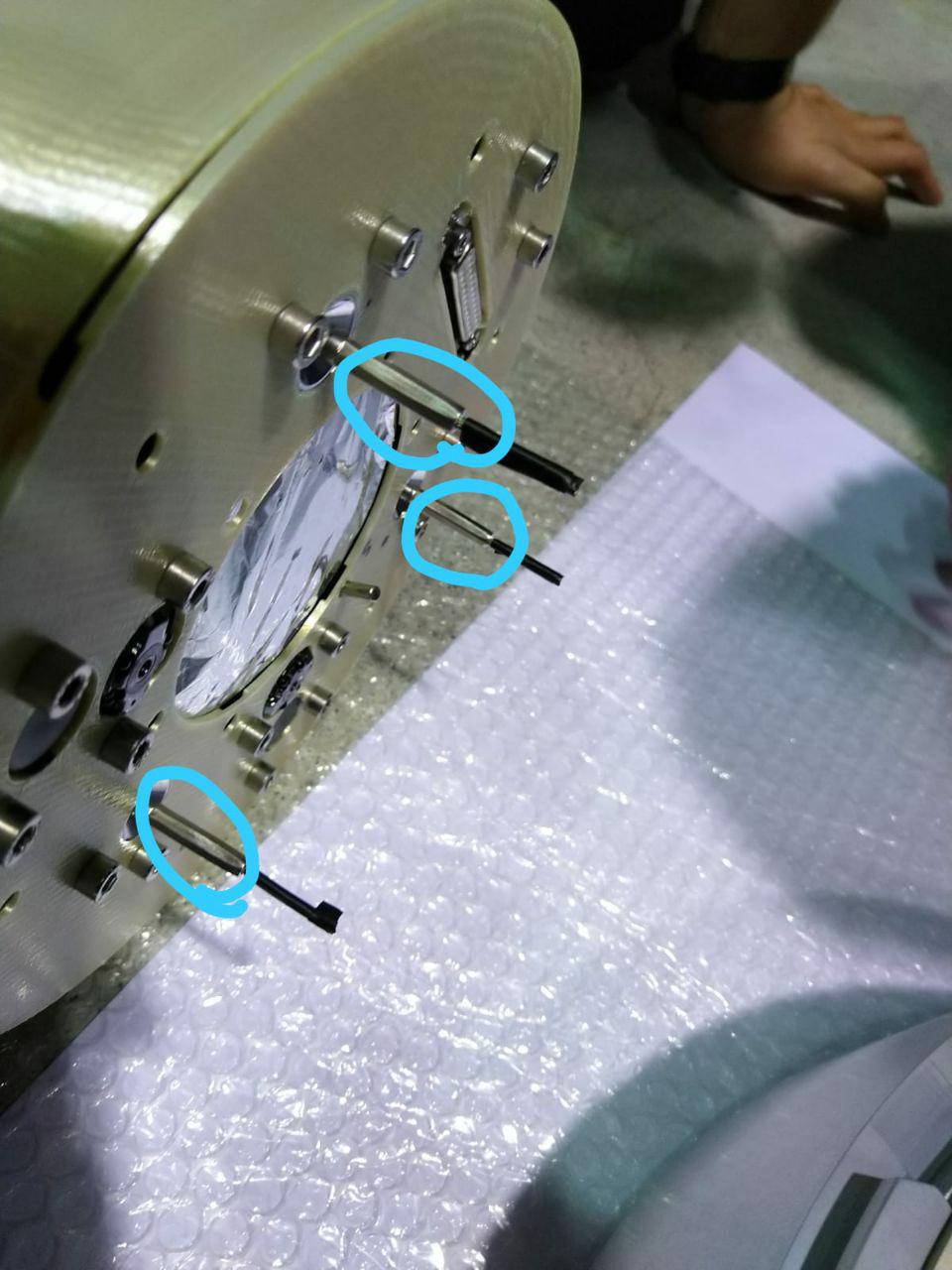

After the wires are cut, the upper part is pushed away by the springs. The cut wires look like this.

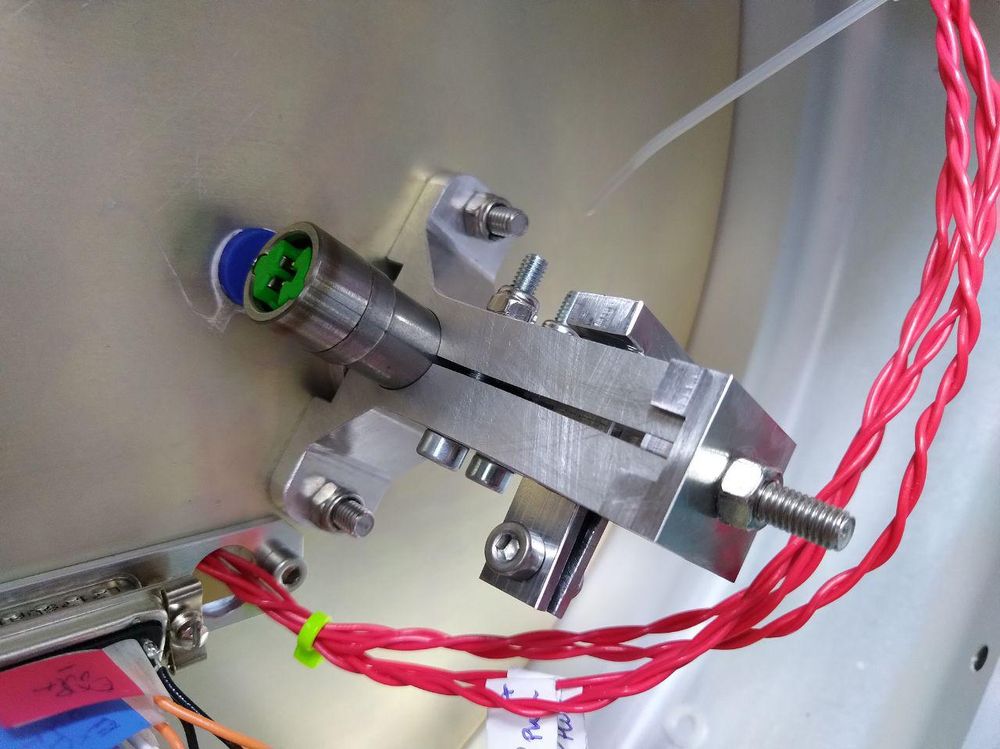

And on the bottom side, below the bulkhead plate, the wires are tensioned by being positioned in parts which were specially designed for this task (and to hold the pyrocutters).

The image above is from December integration week in Bremen, where we used oversized nuts as a simple hack to provide steel surfaces for the nuts on the wire terminals, so they don't damage the aluminium parts. The wire is tensioned by turning the nut on the wire terminal. However, the situation here was not ideal, because the wire also needs to be held in place so it does not rotate. By rotating the wire instead of the nut, the wire can unwind which is undesirable.

Two parts were made to improve the situation - forks to prevent the wire from rotating and a cover for the wire holder. The cover also prevents the holder clamping the wire when the screws that secure the pyrocutter are tightened.

Forks have another intention though. After the steel wires are cut, they fall into the lower parts of the rocket if they are not secured by something. This is exactly what the forks achieve.

However, the tolerances on the current version are not ideal, so we will make another version with a truly minor adjustment where the dimensions will be changed by tenths of millimetres.